Alere Technologies

Production Cleanroom Facility

After a successful tender process, T-SQUARED was appointed as the specialist design and build contractor to undertake a significant programme of works within their Stirling facilities.

The subsequent project saw T-SQUARED undertake the design, build and fit-out a new Production Cleanroom Facility located within their existing Dumyat Block 1 warehouse. The £1M design and build resulted in a high volume medical device manufacturing facility capable of maintaining a working environment with controlled temperature and low humidity. Additional areas constructed included associated storage, warehousing, office and welfare facilities. The project was successfully completed within budget and on time within a 12 week period.

Scope of the project

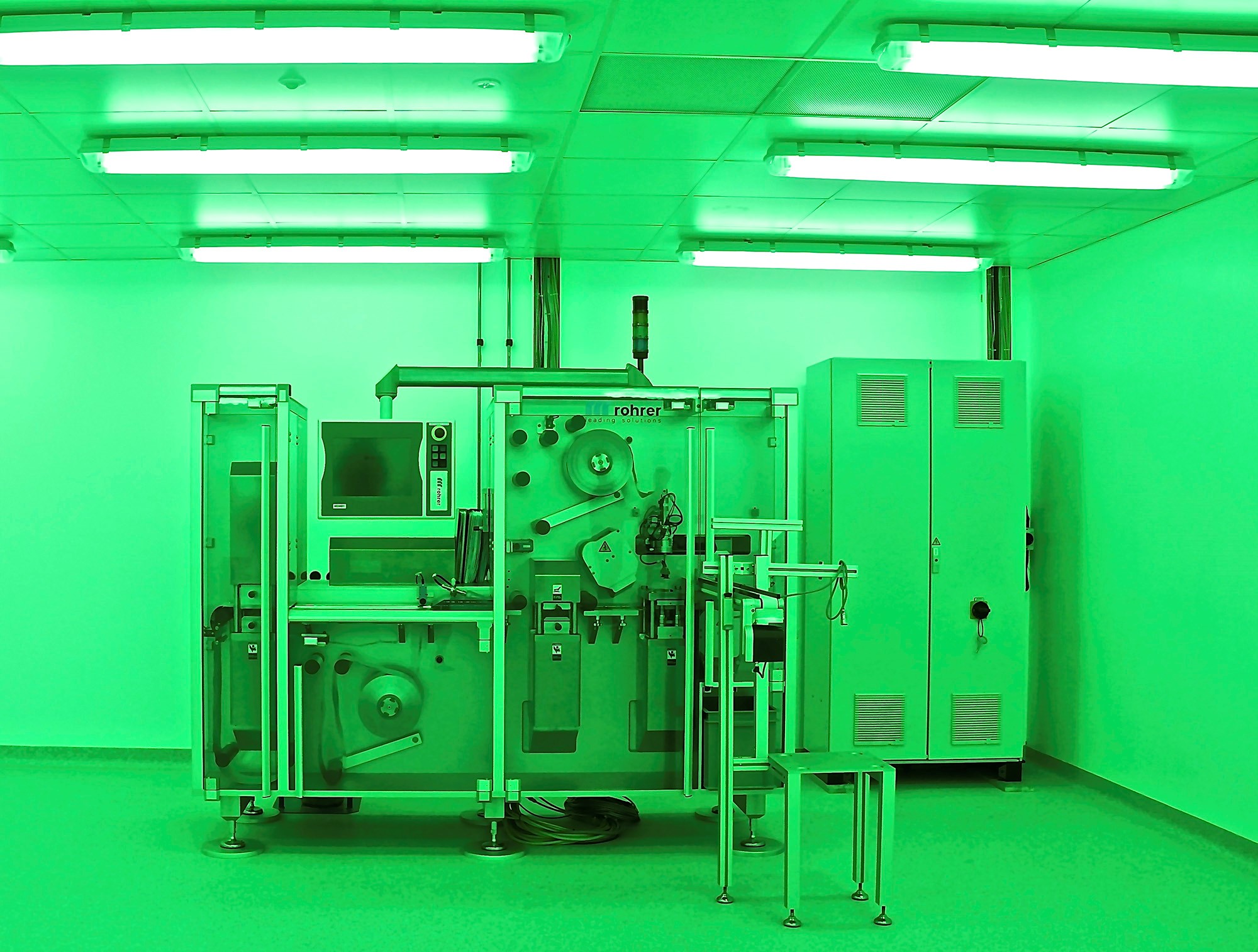

Working closely with Alere Technologies, T-SQUARED developed an innovative, new Production Cleanroom Facility with low levels of RH control and unique lighting requirements which were specifically developed around the Alere Technologies production process.

5% relative humidity cleanroom to ISO7 standards - in line with the client’s production process, extremely low levels of humidity within the cleanroom had to be achieved. The outcome was a facility that achieved 5% RH at 20 deg C - significantly lower humidity levels to those found in the Sahara desert.

Green lighting for the client’s process - to prevent degradation of a chemical component used within the client’s product, lighting of a specific wavelength had to be designed and installed. “Green Light” exhibited the correct wavelength however the light output per fitting was considerably lower than standard white light. During the development stages, a detailed design study was carried out to ensure that the required lux levels were achieved.

The scope of work included

- Fabric Works (Walls, Floors, Ceilings, Doors)

- Cleanroom Production HVAC Systems

- Toilet, Offices and Tea Prep HVAC Systems

- Electrical Services

- LPHW Heating System

- Chilled Water System

- Munters Dehumidifier Unit

- Automatic Controls

- Machine utilities including 110V machine supplies

- Natural Gas Pipework

- N2 Pipework

- Compressed Air Pipework

- External Cold Store Installation

- Steelwork (Walls and Stairs)

- Passenger Lift

T-SQUARED was set an extremely aggressive timeline for the completion of the project. The facility was finished to a very high standard within agreed time and cost constraints. All involved in the project are extremely pleased with the result.

Andy Johnston

Facilities / Health & Safety Manager, Alere Technologies